Casting techniques have come a long way since their inception, and as we head into the future, innovations and advancements are set to take them to the next level. The manufacturing industry has relied on casting techniques for decades, and these methods continue to evolve to meet the ever-changing demands of modern technology. Among the many casting techniques available, centrifugal casting has emerged as a top contender due to its unique benefits. In this blog, we’ll explore the future of casting techniques and how advancements in centrifugal casting technology are revolutionizing the manufacturing process. From enhanced precision to increased efficiency, let’s take a glimpse into the future of casting.

Advantages of Centrifugal Casting Technique

Centrifugal casting is a process that involves pouring molten metal into a spinning mold to create a uniform shape. This technique offers several advantages over traditional casting methods, including:

- Enhanced Quality: Centrifugal casting ensures a more uniform distribution of the metal, resulting in fewer defects and greater consistency in the final product.

- Improved Efficiency: By using centrifugal force to distribute the molten metal, centrifugal casting can be a faster process than other casting methods, reducing production time and costs.

- Reduced Waste: The centrifugal casting process generates less scrap metal and material waste, making it a more sustainable and environmentally friendly option.

- Versatility: Centrifugal casting can be used to create a wide range of shapes and sizes, including complex and asymmetrical designs.

- High Strength: The directional solidification of the metal during centrifugal casting can result in a more uniform grain structure and improved mechanical properties, such as higher strength and durability.

- Reduced Machining: Parts produced by centrifugal casting often require less machining than those produced by other casting methods, which can further reduce production costs and time.

Overall, the advantages of centrifugal casting make it an attractive option for many industries, including aerospace, automotive, and manufacturing. As the technology continues to evolve and improve, it is likely that we will see even greater adoption of this technique in the future.

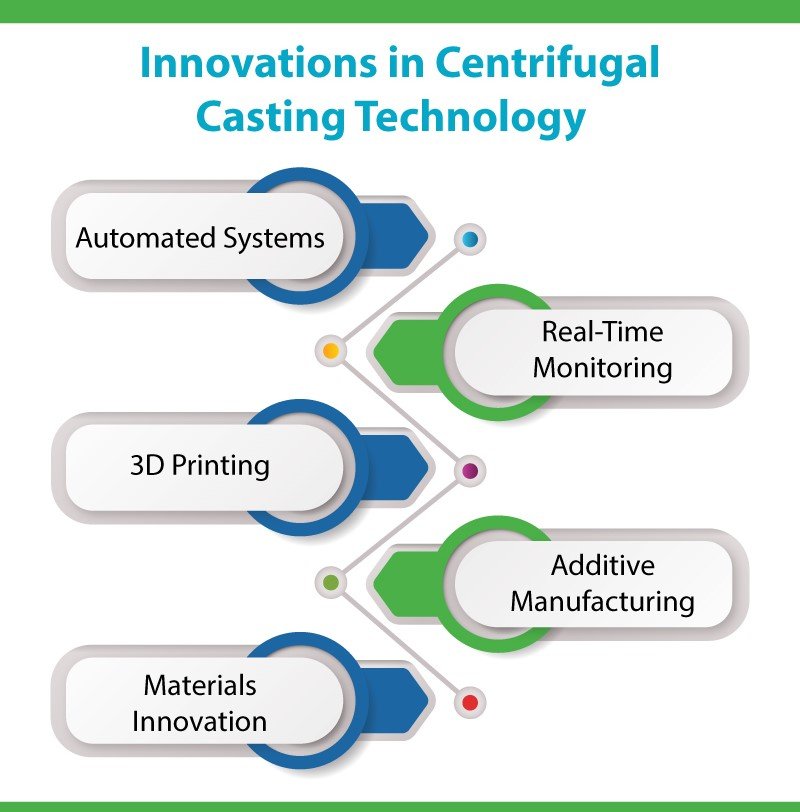

Innovations in Centrifugal Casting Technology

Centrifugal casting has been in use for over a century, and as technology continues to advance, new innovations are being developed to further improve the efficiency, quality, and versatility of the process. Some of the recent innovations in centrifugal casting technology include:

- Automated Systems: With the help of automation and robotics, centrifugal casting can be a more efficient and consistent process. Automated systems can handle tasks such as mold filling, metal pouring, and mold removal, reducing the need for manual labor and improving the accuracy of the process.

- Real-Time Monitoring: Advances in sensor technology and data analysis allow for real-time monitoring of the centrifugal casting process. By monitoring factors such as temperature, pressure, and rotation speed, manufacturers can make adjustments on the fly to improve quality and consistency.

- 3D Printing: Combining 3D printing with centrifugal casting can allow for the creation of more complex and intricate molds. 3D printing can also help reduce production time and costs by eliminating the need for expensive tooling.

- Additive Manufacturing: In addition to 3D printing, other forms of additive manufacturing such as laser powder bed fusion and binder jetting can be used to create molds for centrifugal casting. This can allow for greater design flexibility and faster prototyping.

- Materials Innovation: New materials such as high-temperature alloys and advanced ceramics are being developed for use in centrifugal casting. These materials can improve the strength, durability, and performance of cast parts.

These innovations in centrifugal casting technology have the potential to revolutionize the manufacturing industry by reducing production costs, improving quality and consistency, and enabling the creation of more complex and intricate parts. As the technology continues to advance, it is likely that we will see even more innovations in the future.

Precision Casting: The Future of Manufacturing

Precision casting, also known as investment casting or lost-wax casting, is a process that involves creating a wax pattern of the part to be cast and then creating a mold around the pattern. The wax is then melted and replaced with molten metal, which solidifies in the mold to create a highly accurate and detailed part. This technique offers several advantages over other casting methods, making it a promising candidate for the future of manufacturing.

- Increased Accuracy: Precision casting can create highly detailed and accurate parts with tight tolerances. This makes it ideal for producing complex parts with intricate shapes and geometries.

- Consistent Quality: The process of precision casting can create parts with uniform density and minimal defects, resulting in consistent quality across a large production run.

- Versatility: Precision casting can be used to cast a wide range of materials, including alloys, steels, and even precious metals. This makes it a versatile option for many different applications.

- Reduced Machining: Parts produced by precision casting often require minimal post-processing, reducing the need for machining and resulting in faster production times and lower costs.

- Sustainable: Precision casting generates less waste than other casting methods and can be used to create complex shapes and geometries without the need for additional tooling, reducing material waste and saving energy.

As technology continues to evolve, precision casting is expected to become an even more important part of the manufacturing industry. With the ability to produce highly accurate and detailed parts with minimal post-processing, precision casting is well-positioned to play a critical role in the future of manufacturing.

Casting with Additive Manufacturing (3D Printing)

Casting with additive manufacturing, also known as 3D printing, is a technique that combines the versatility of 3D printing with the precision and accuracy of traditional casting methods. This process involves using a 3D printer to create a mold or pattern, which is then used to cast the final part using a variety of casting techniques, including centrifugal casting. One of the benefits of using additive manufacturing for casting is the ability to create highly complex and intricate molds that would be difficult or impossible to create using traditional methods. This allows for greater design flexibility and can result in parts with unique shapes and geometries.

In addition to creating molds, 3D printing can also be used to create patterns for investment casting. This process involves printing a wax or resin pattern that is then used to create the mold for the final part. Investment casting using 3D printing can result in highly accurate and detailed parts with tight tolerances. When combined with centrifugal casting, 3D printing can be used to create molds that are highly resistant to the high rotational forces involved in the casting process. This can result in parts with greater strength and durability.

Another benefit of using additive manufacturing for casting is the ability to rapidly prototype and iterate designs. 3D printing allows for quick and easy changes to the mold or pattern, reducing the time and cost of the prototyping process. While still, a relatively new technique, casting with additive manufacturing has the potential to revolutionize the manufacturing industry by enabling greater design flexibility, faster prototyping, and improved part quality. As technology continues to advance, it is likely that we will see even more innovations in this field, further enhancing the capabilities of this exciting new casting technique.

The Role of Artificial Intelligence in Casting

Artificial intelligence (AI) is transforming many industries, and casting is no exception. In recent years, AI has been increasingly used in casting to improve efficiency, accuracy, and overall part quality. One of the ways that AI is being used in casting is through the optimization of the casting process. AI algorithms can be used to simulate the casting process and identify potential defects before production even begins. This allows manufacturers to make adjustments to the process and prevent costly mistakes.

AI can also be used to analyze casting data to identify patterns and trends that can inform future production decisions. For example, machine learning algorithms can be trained to analyze the data from past production runs to predict the likelihood of defects or to identify optimal casting parameters for a given part. In addition to improving the casting process itself, AI can also be used to improve the post-processing stage. AI algorithms can be used to analyze the surface quality of cast parts and identify areas that require additional finishing or polishing.

Another way that AI is being used in casting is through the use of predictive maintenance. By monitoring data from casting equipment, AI algorithms can predict when maintenance is required, reducing downtime and preventing costly equipment failures. As AI technology continues to advance, we can expect to see even more innovations in the field of casting. From optimizing the casting process to improving part quality and reducing downtime, the role of AI in casting is set to become increasingly important in the years to come.

Sustainability and Casting: Materials and Processes

Sustainability is becoming increasingly important in the manufacturing industry, and casting is no exception. The use of sustainable materials and processes in casting can help reduce waste and minimize the environmental impact of manufacturing. One way that casting can be made more sustainable is through the use of recycled materials. Many casting alloys can be made using recycled metal, reducing the need for virgin materials and minimizing waste. Recycling also reduces the carbon footprint associated with mining and refining raw materials. Another way to make casting more sustainable is through the use of renewable energy sources. Many foundries are transitioning to renewable energy sources such as solar or wind power to reduce their carbon emissions. This not only benefits the environment but can also lead to cost savings in the long term.

The use of sustainable casting processes can also help reduce waste and energy consumption. For example, investment casting, also known as lost-wax casting, is a process that uses a reusable mold, reducing the need for new molds for each casting run. This reduces material waste and energy consumption associated with creating new molds. Other sustainable casting processes include sand casting, which uses sand molds that can be recycled and reused, and die casting, which uses permanent molds that can be reused for multiple casting runs. In addition to sustainable materials and processes, casting can also be made more sustainable through efficient use of resources. This includes reducing water consumption and minimizing scrap and waste during the casting process. Overall, the use of sustainable materials and processes in casting can help reduce the environmental impact of manufacturing while also providing cost savings and improved efficiency. As sustainability continues to be a growing concern in the industry, we can expect to see more focus on sustainable casting practices in the years to come.

Conclusion: The Future of Casting is Here

As an industry leader in critical cleaning and coating solutions, the MicroCare group is well-positioned to help manufacturers navigate the changing landscape of casting. Their expertise in cleaning and coating technologies can help ensure that cast parts are of the highest quality and meet the demands of modern manufacturing. Through partnerships and collaborations with manufacturers, the MicroCare group is actively working to develop new technologies and processes that address the challenges facing the casting industry. From sustainable materials and processes to advancements in AI and 3D printing, the MicroCare group is at the forefront of innovation in the industry.