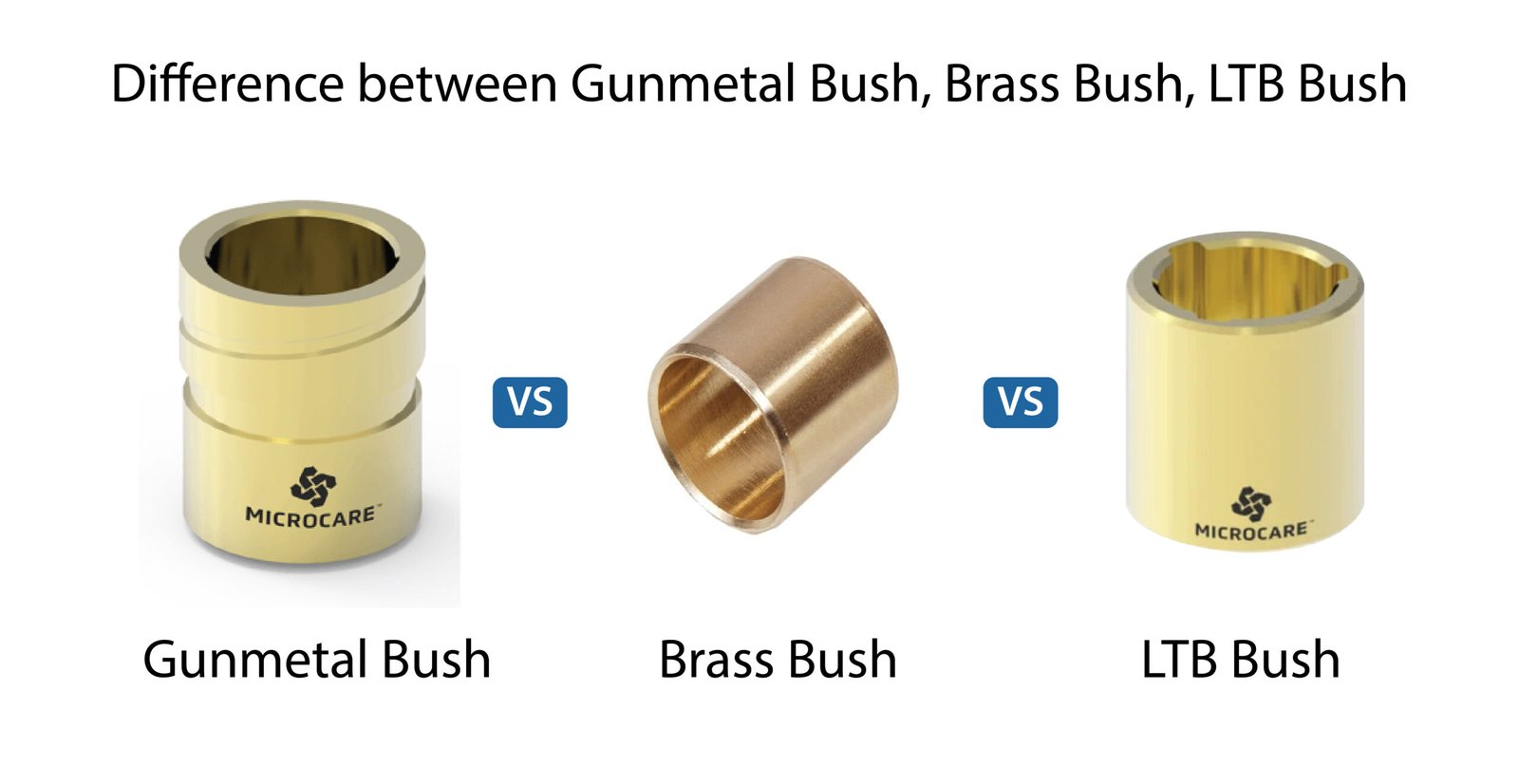

High grade bushes are particularly made from materials like gunmetal bush, brass, and bronze. Different alloys have various characteristics, such as hardness, resistance to wear and heat, etc. We manufacture the appropriate material with specified dimensions for you based on applications or client requirements.

Our bushes are constructed from premium-grade material that complies with global standards and property requirements. We utilize the suitable material to adhere to the composition and get the finest attributes. Our gunmetal bush are created from virgin metals for alloying, greatly reducing impurities at the source and giving our goods the greatest qualities. The bushes have good bearing qualities because they have been machined and honed to smooth surface finishes. Our goods are built to function and last a long time thanks to the ideal material and careful construction.

Specifications: Brass, particularly in accordance with European Grades

- Bronze phosphorous

- Bronze with lead

- Bronze Aluminum

- Manganese Bronze

Spring Bushes made of gunmetal

In laminated spring eyes and shackles, gunmetal bush are frequently employed. These bushes must withstand a variety of strains and loads. Our spring bushes, which are constructed of the proper material, are well-suited to withstand this. These bushes come with precisely carved grooves that are meant to hold oil for lubrication.

Bushes, a gun metal kingpin

Kingpin bushes need to be manufactured with extreme accuracy because to their purpose. These kingpin bushes are produced to the specifications of the client and are offered in both machined and pre-machined sizes as needed. With features and proudly say that ltb bush manufacturers in india that may serve the task well and give a longer life than usual, high superior quality grades are used.

Gun Metal bushes for use with heavy machines

Heavy machinery regularly employs gunmetal bush for a variety of purposes. These bushes are made by us according to client specifications and needs. They are of the highest quality to function in any challenging settings, but they must complete their work without fail. Every time, the performance of our product exceeds expectations.

Other automotive and engineering applications for gun metal bushes

In addition to the aforementioned uses with the gun metal bush manufacturers in different countries but there are many company and the best thing is that gun metal bushes are also used in brakes, gearboxes, connecting rods, steering, and many more components. According to the needs and specifications of the customer, we design and produce bushes for a variety of applications. A particularly useful alloy is brass. It becomes harder than any of the basic metals when copper and zinc are fused together, and it keeps its shape well while still being able to be worked. It won’t bond to steel when it comes into touch with steel machine shafts since the two metals are different. These characteristics make brass a perfect metal for bushings.

Bushings for the propeller shaft

Eventually, the propeller shaft must pass through the hull of a boat or ship and connect to the propeller. On the propeller shaft, brass bush are frequently employed. Brass has the additional virtue of not rusting, making it the perfect metal for aquatic environments. Marine bushings with two parts can also be found. They feature a steel outer shell and a pressed-in brass inner bushing that rests against the shaft. Steel is more durable than brass, therefore an exterior shell made of steel can withstand pressures. Brass will be used for the inner shell, which will house the spinning shaft. Brass back composite bearings are the name given to these bushings.

Bushing for a water pump

Every automobile engine that uses water cooling includes a water pump, and the pump’s primary shaft is bushed in brass. Brass is used for the shaft bushing due to its anti-rust and friction-reducing qualities when in contact with steel. To stop water leakage, a rubber seal is attached to the bushing’s inside. A trace quantity of fluid can pass through this seal and lubricate the bushing. Manufacturers almost seldom advise using just pure water. Instead, they advise using fluid with built-in lubricants like antifreeze to assist reduce friction between the bushing and the water pump shaft.

EF = Electromotive Force

Brass bushings on either side of the armature, which spins, are commonly used to hold the motor shaft in electric motors. Brass bush may be used for a variety of purposes. It’s cheap and accessible, for starters. Second, it reduces oil consumption thanks to its anti-friction properties. Third, common machine tools may be used for its production with little difficulty.

Drag Bearings

A machine shaft frequently glides into and out of an assembly rather than rotating. This action is used by desktop printers to move the print head back and forth over the paper. If you have a printer, have a look at the ink cartridge’s sliding carriage. The carriage is supported by shafts made of polished steel. The bushings for the carriage slide are frequently composed of brass.

Describe LTB Bush.

Leukotriene B4 (LTB-4) Brass surface finishing.

In the region where the water circulates, these plants serve as a bearing. Our extensive selection of LTB bushes can also be modified to meet the needs of the client. Our bushes may be tailored to the customers’ demands and requirements, and they are offered at costs that are among the lowest in the industry.

Experienced and qualified

We work with highly skilled and knowledgeable personnel to provide Submersible Pump LTB 4 Bronze Bushing. Under the direction of our professionals, the supplied pump bushing is flawlessly created using premium-quality raw materials and cutting-edge technology. Additionally, the engineering and construction sectors make substantial use of the provided Submersible Pump Bushing.

Call To Action

As a prominent Indian pump parts manufacturer, Microcare is a name you can trust and a brand you can depend on. Pump spares, gunmetal bushes, brass bush, ltb bushes, ltb bush manufacturers in india, and gunmetal bush are all products that Microcare is well-known for producing. Microcare has always set the bar high in terms of quality, efficiency, and on-time delivery. Microcare has been around for almost 30 years, and in that time it has become a technological and quality standard bearer in its field. Microcare provides a wide selection of LTB bushes, each of which may be modified to meet the needs of the client. Microcare bushes are among the most cost-effective options available and may be customized to match the requirements of particular clients.